stud connector

- group name

- Shear Connector

- Min Order

- 20000 piece

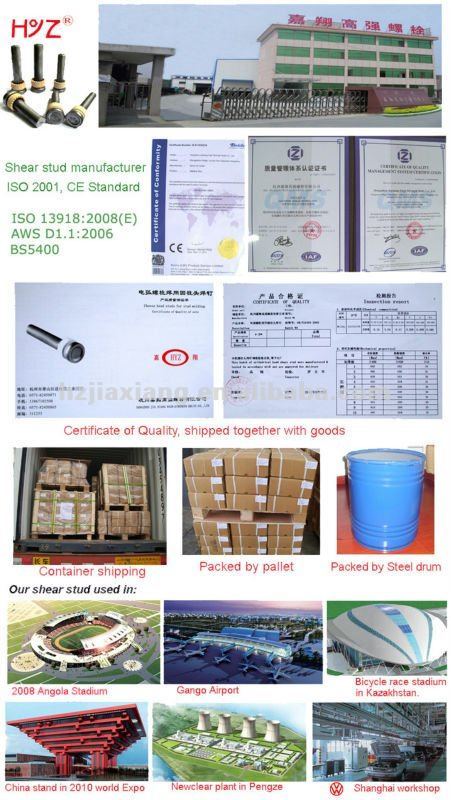

- brand name

- HYZ

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram, Westem Union

- update time

- Wed, 06 Mar 2013 01:05:00 GMT

Paramtents

Length 40~300

Type Common Nail

Shank Diameter 10~25

Head Diameter 18~40

Material Steel

Packging & Delivery

-

Min Order20000 piece

Briefing

according to GB/T10433 ,ANSI/AWSD1.1-92,JISB1198- 82,ISO13918,AWS D1.1

Detailed

shear connector/stud welding

according to GB/T10433 ,ANSI/AWSD1.1-92,JISB1198- 82,ISO13918,AWS D1.1

shear connector/stud welding

Stud welding is a form of spot welding where a bolt or specially formed nut is

welded onto another metal part. The bolts may be automatically fed into the

spot welder.

shear connector/stud welding

Weld nuts generally have a flange with small nubs that melt to form the weld.

Studs have a necked down, un-threaded area for the same purpose. Weld

studs are used in stud welding systems.

shear connector/stud welding

Arc studs range from a #8 to 1 1/4" diameter. The lengths are variable from

3/8" to 60" (for deformed bars). Arc studs are typically loaded with an

aluminum flux ball on the weld end which aids in the welding process.

shear connector/stud welding

Stud welding, also known as stud arc welding, joins a stud and another piece

of metal together. The stud is usually joined to a flat plate by using the stud

as one of the electrodes. The polarity used in stud welding depends on the

type of metal being used. Welding aluminum, for example, would usually

require direct-current electrode positive (DCEP). Welding steel would require

direct-current electrode negative (DCEN). Stud welding uses a type of flux

called a ferrule, a ceramic ring which concentrates the heat generated,

prevents oxidation and retains the molten metal in the weld zone. The ferrule

is broken off of the fastener after the weld is completed. Portable stud welding

machines are available. Welders can also be automated, with controls for

arcing and applying pressure. Stud welding is very versatile. Typical

applications include automobile bodies, electrical panels, shipbuilding and

building construction. Shipbuilding is one of the oldest uses of stud welding.

Stud welding revolutionized the shipbuilding industry. All other manufacturing

industries can also use stud welding for a variety of purposes.